Managing with Data

Many of the best leaders I know, even the ones in AI technology, make decisions based on gut feel. That intuition is based on a mix of past experiences, biases, and raw confidence, but it often, and sometimes surprisingly, serves them well. They don’t always make the right decision, but it can lead them in interesting directions.

People like chess masters and poker players do this naturally well; they take the available information, sense an opportunity, and make a choice. However, for the rest of us, some decisions can be paralyzing without more information to help guide us.

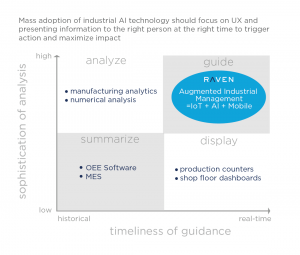

That’s where data and technology come in handy. It’s what we call augmented management.

Augmented management is the use of data to augment one’s ability to know what change to make. It’s the intersection of data and human ingenuity. Breaking it down, augmented management is the use of quantifiable information to help us:

- Recognize what change to make; and

- Know how to present the action.

Let’s apply it to the manufacturing industry. Here are some interesting facts:

- There are about 12.75 million manufacturing workers in the United States, representing 8.6 percent of the workforce.

- Output per hour for all workers in the manufacturing sector has increased by more than 5 times since 1987.

- In the last 20 years, there have been massive advancements in technology to support manufacturers and mine data.

Given AI’s advancements, why are we using the same labour intensive tools, like Excel and whiteboards, to analyze data? Worse yet, what are we doing with that data? Are we making a change based on that information?

Here’s another question: Why don’t we let AI tools make all our decisions for us?

The simple answer is that humans are much better decision makers than any technology. Like chess masters, we use data but it is weighed against other weighty factors such as emotion, experience, and intuition.

Let me share an example. One of our customers had a manually intensive process. Every operator approached the challenge differently and found ways to inserts parts into the machine in a way that suited them best. However, the data showed one operator was particularly fast, heads and shoulders above everyone else. He wasn’t loading the machine at lightning speed or had particularly dextrous hands. He simply found a new way to load the machine that was more efficient. No AI gadget could have come up with an innovative solution – it was something he learned through trial and error. As a result, he taught everyone in the plant unique method, making it a new best practice.

You can train or incentivize a team to perform faster, but imagine if you can find something that makes everyone’s process easier and more efficient.

In a more universal example, take Waze. It uses input from the driving choices humans make to come up with the best route to a destination. Its efficacy is directly related to the real-time decisions we make and the input we provide. The sweet spot is a mix of sophisticated analysis with immediate input.

This is augmented management in action and it’s the next wave of lean manufacturing. Technology has gotten to the point where we can obtain endless amounts of data. But without the input of humans and an actionable change, that data is useless.